Proprietary Procurement Systems

Component-Level Pricing & Direct Sourcing Platform

Cost Control Through Integrated Procurement

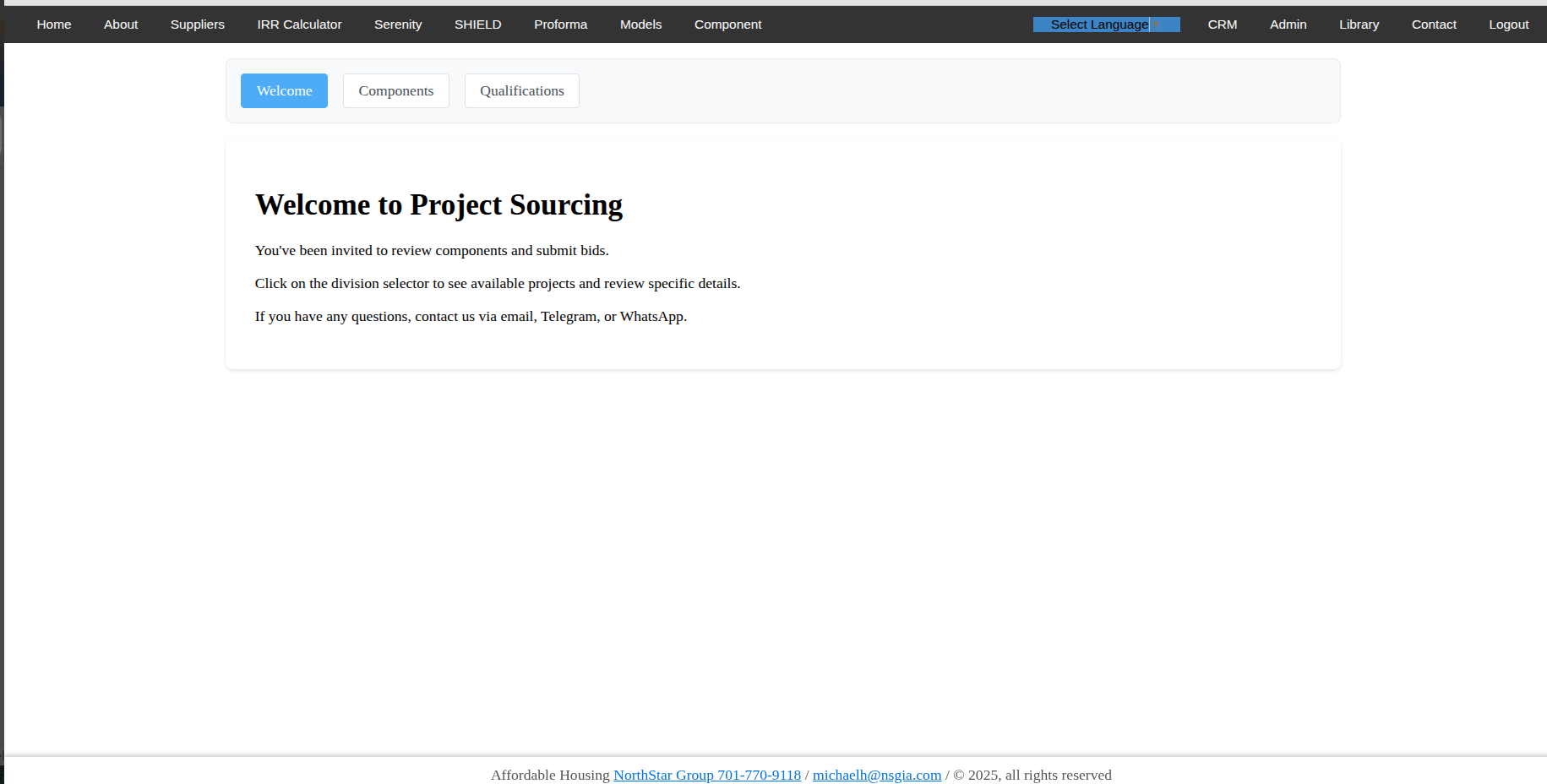

Project Sourcing Portal - Supplier Qualification and Bidding Interface

North Star Group developed a proprietary procurement system that eliminates traditional general contractor markup through component-level pricing and direct supplier relationships. This systematic approach provides cost control and transparency for development projects.

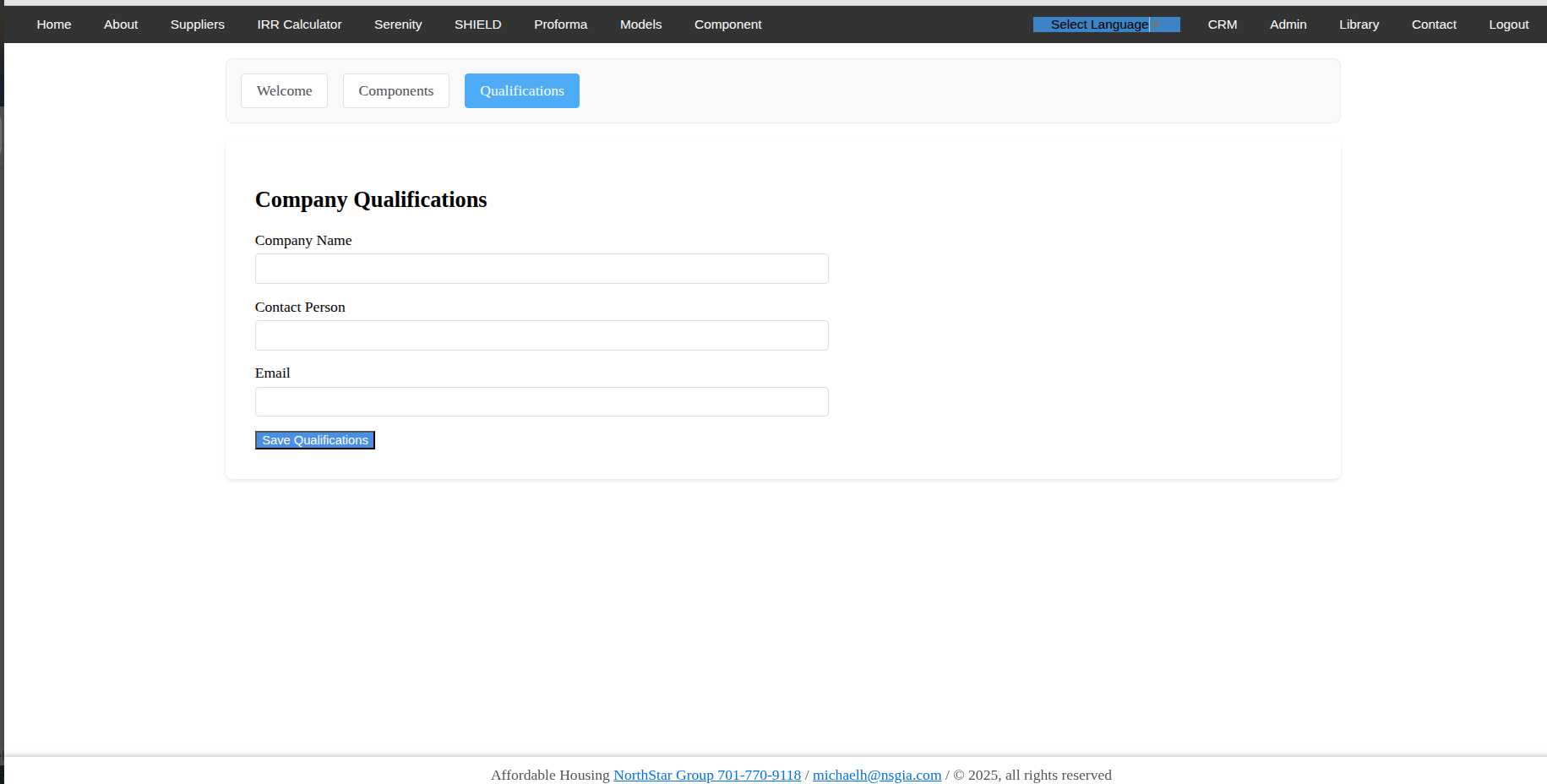

Supplier Qualification Portal - Standards and Documentation Requirements

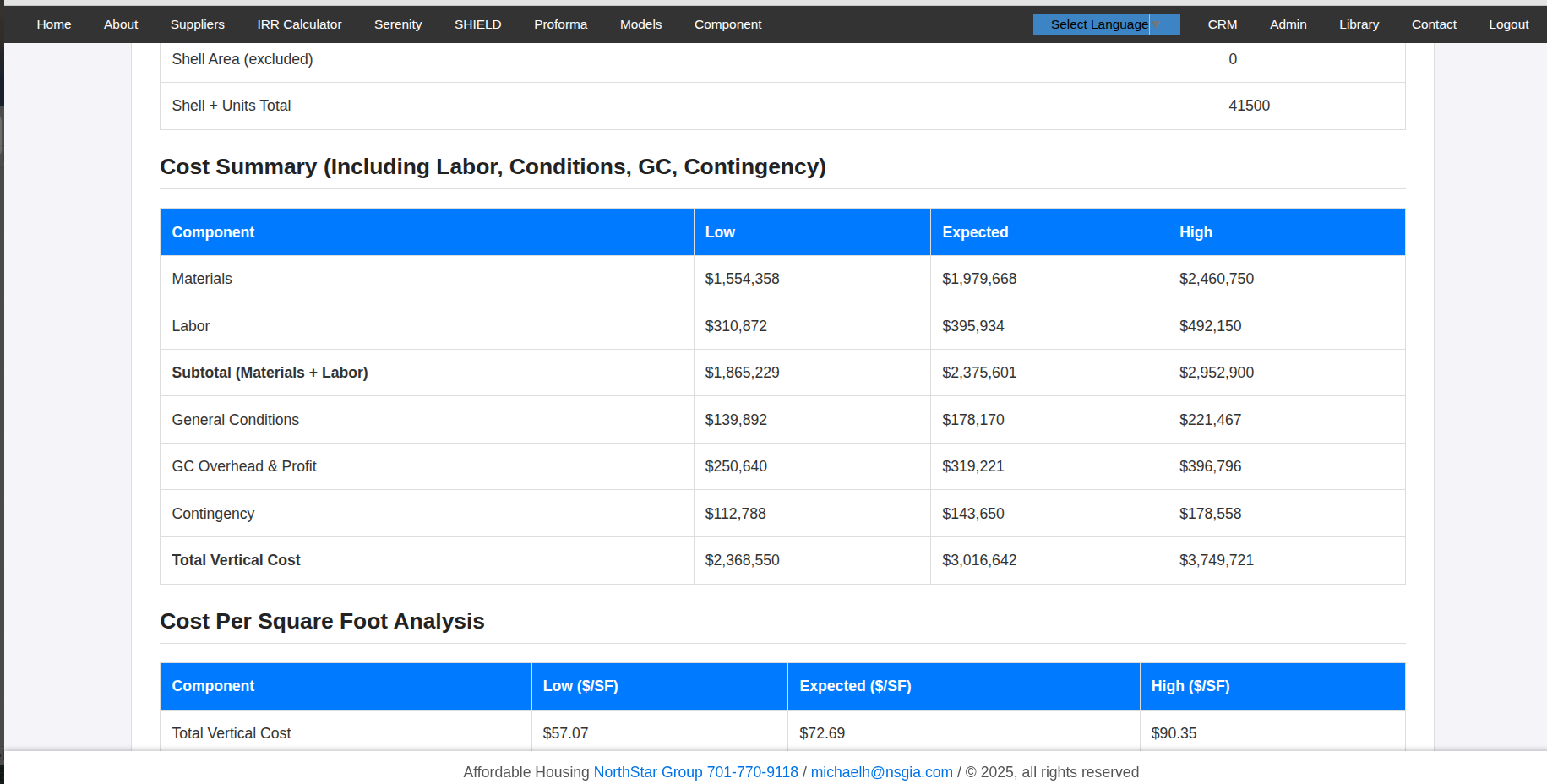

Cost Reduction: Component-level pricing and direct sourcing eliminates 15-25% general contractor markup on materials and subcontractor costs. For a $9 million project, savings range from $1.35 to $2.25 million.

The system integrates with component management, providing real-time cost tracking, supplier performance monitoring, and quality assurance throughout procurement and construction.

Component-Level Design Integration

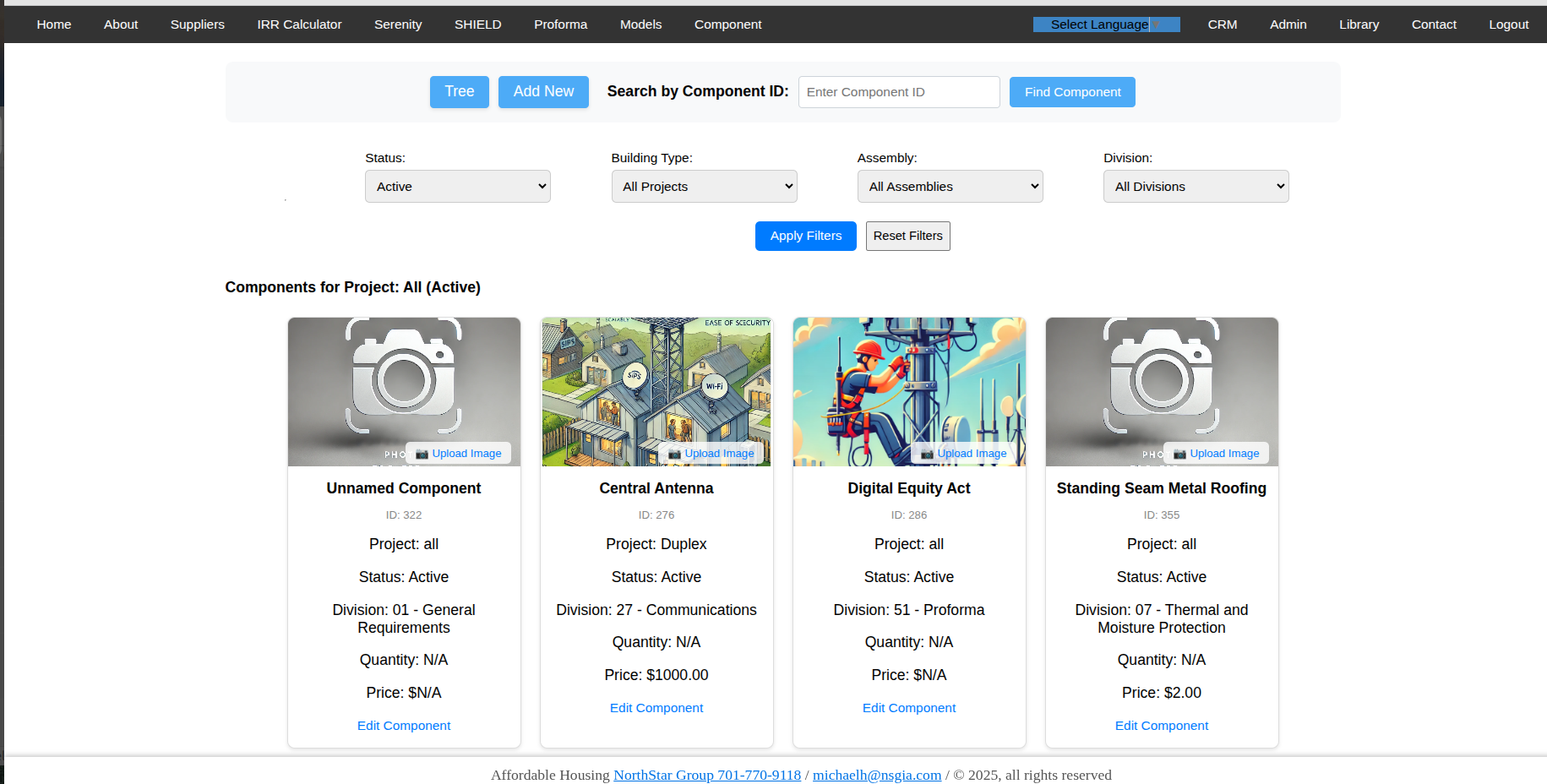

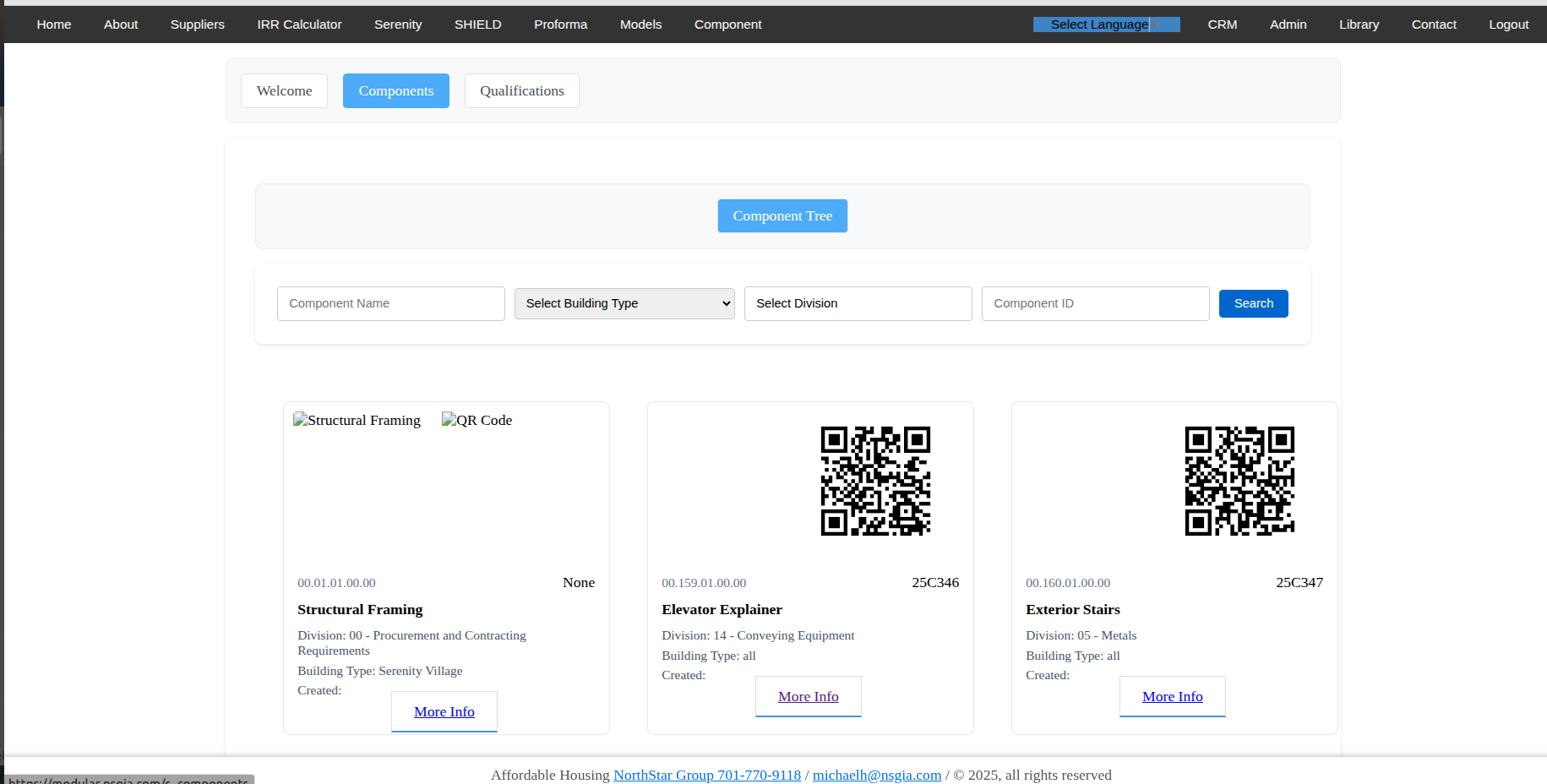

Component Management - Adding Components with Specifications

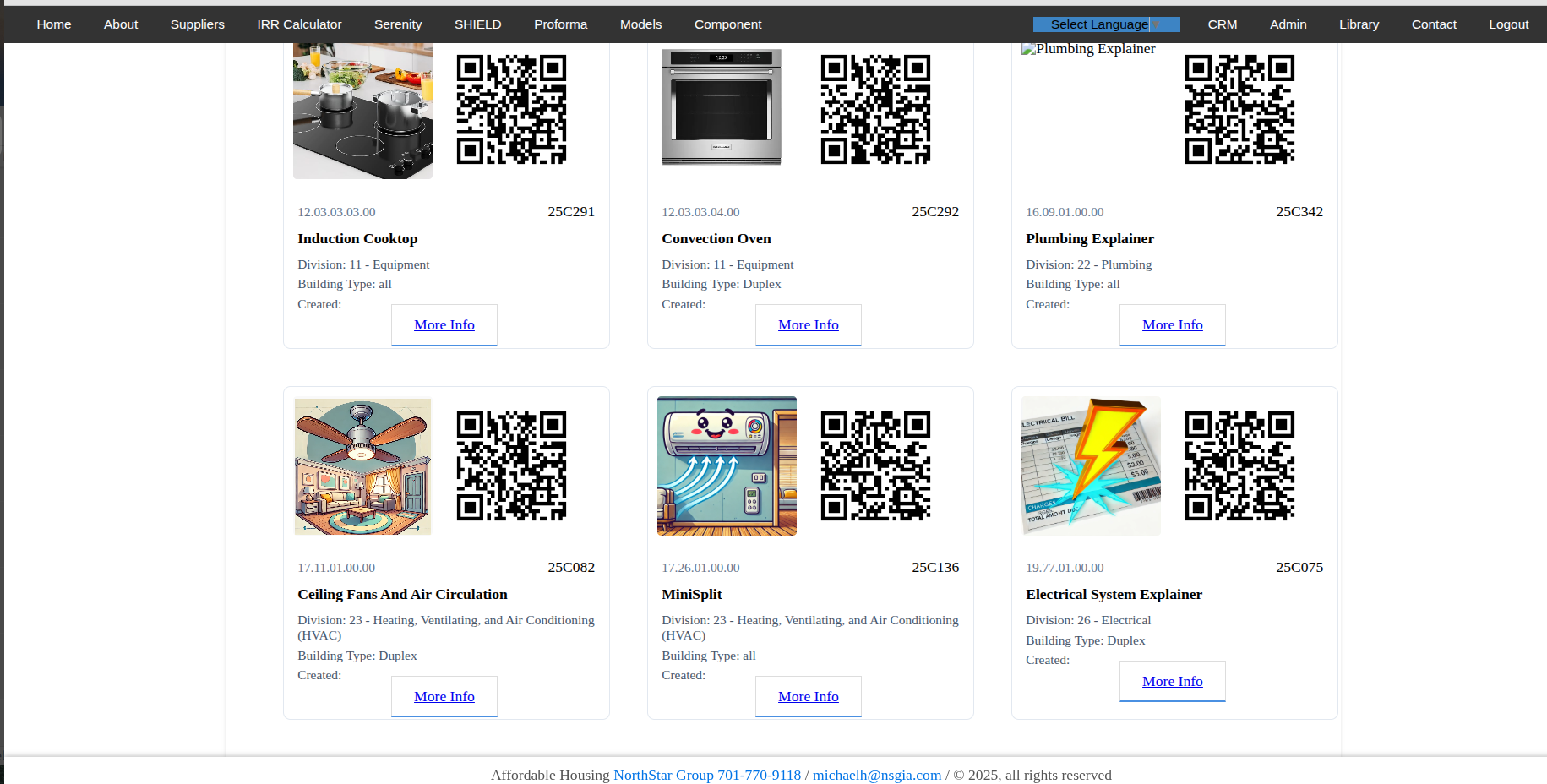

QR Code Integration - Component Tracking and Documentation

Each component is catalogued with detailed specifications, performance requirements, and QR code tracking. Complete traceability from design through installation.

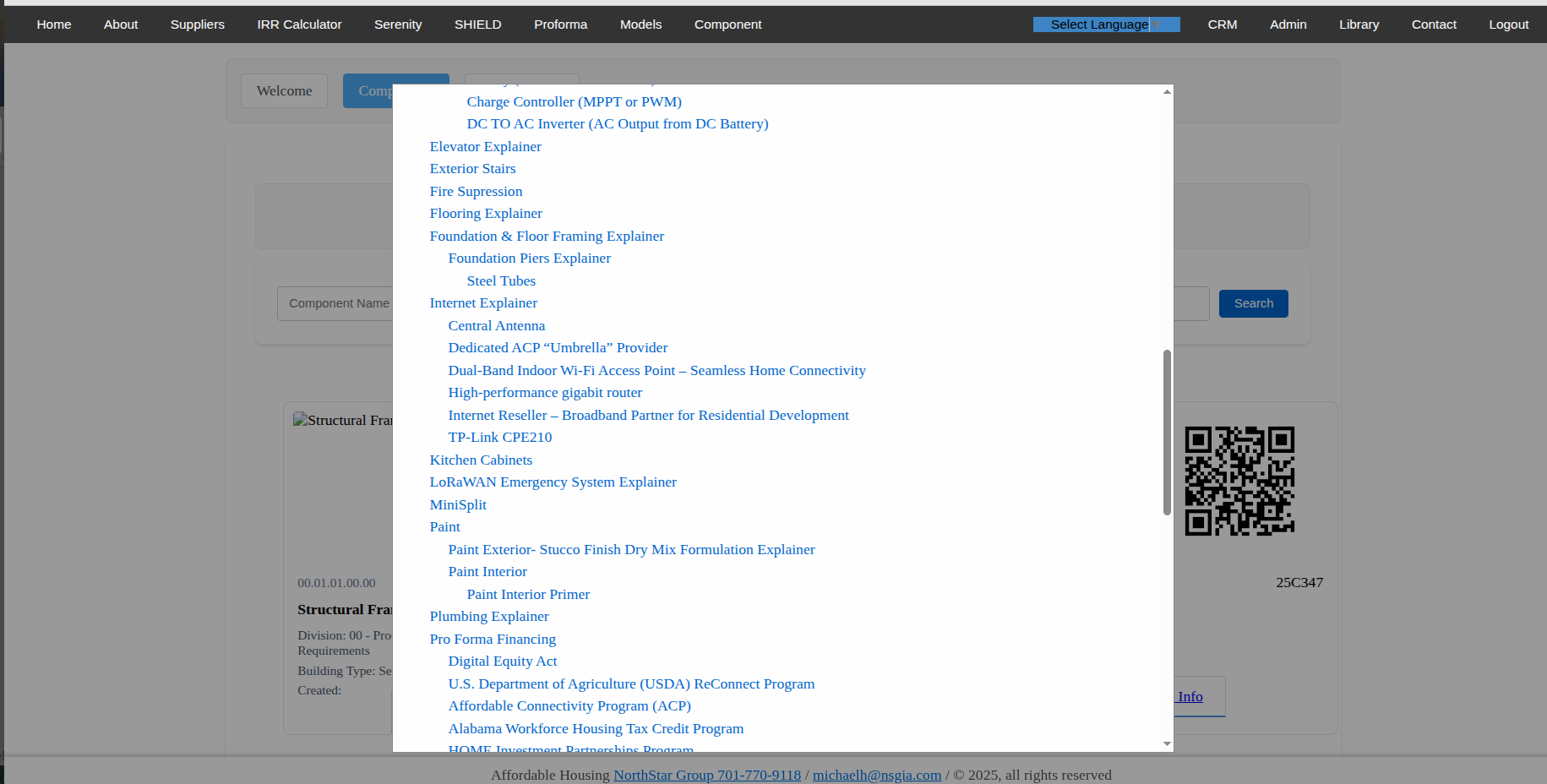

Component Tree - Hierarchical Project Organization

Component Tree Expanded - Detailed Breakdown

Cost Analysis System

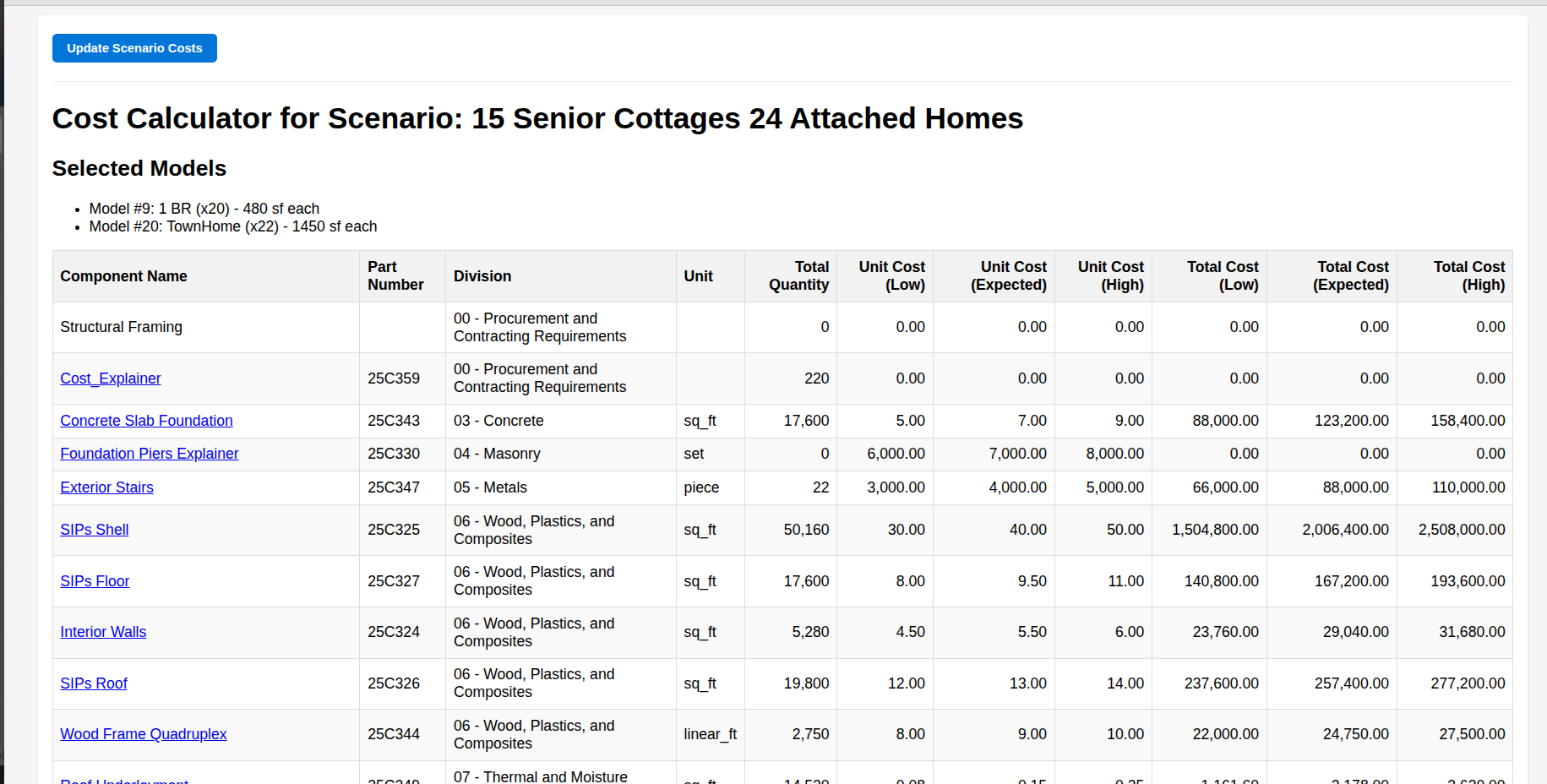

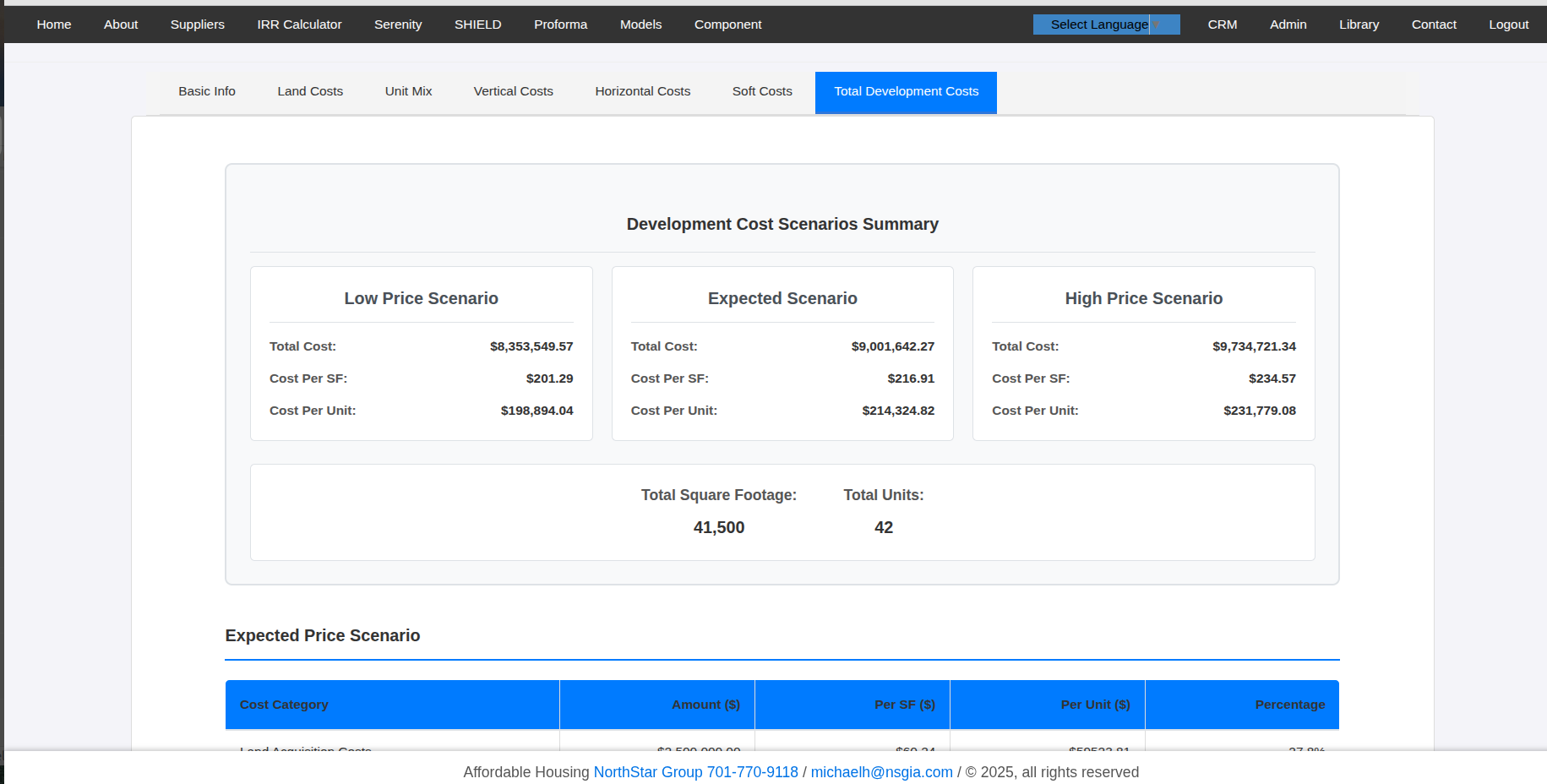

Cost Calculator - Low/Expected/High Scenario Modeling

Cost Summary - Aggregated Project Totals

Tradesman-specific reports track pricing history and performance. Institutional memory builds with each project—pricing data, supplier reliability, delivery performance.

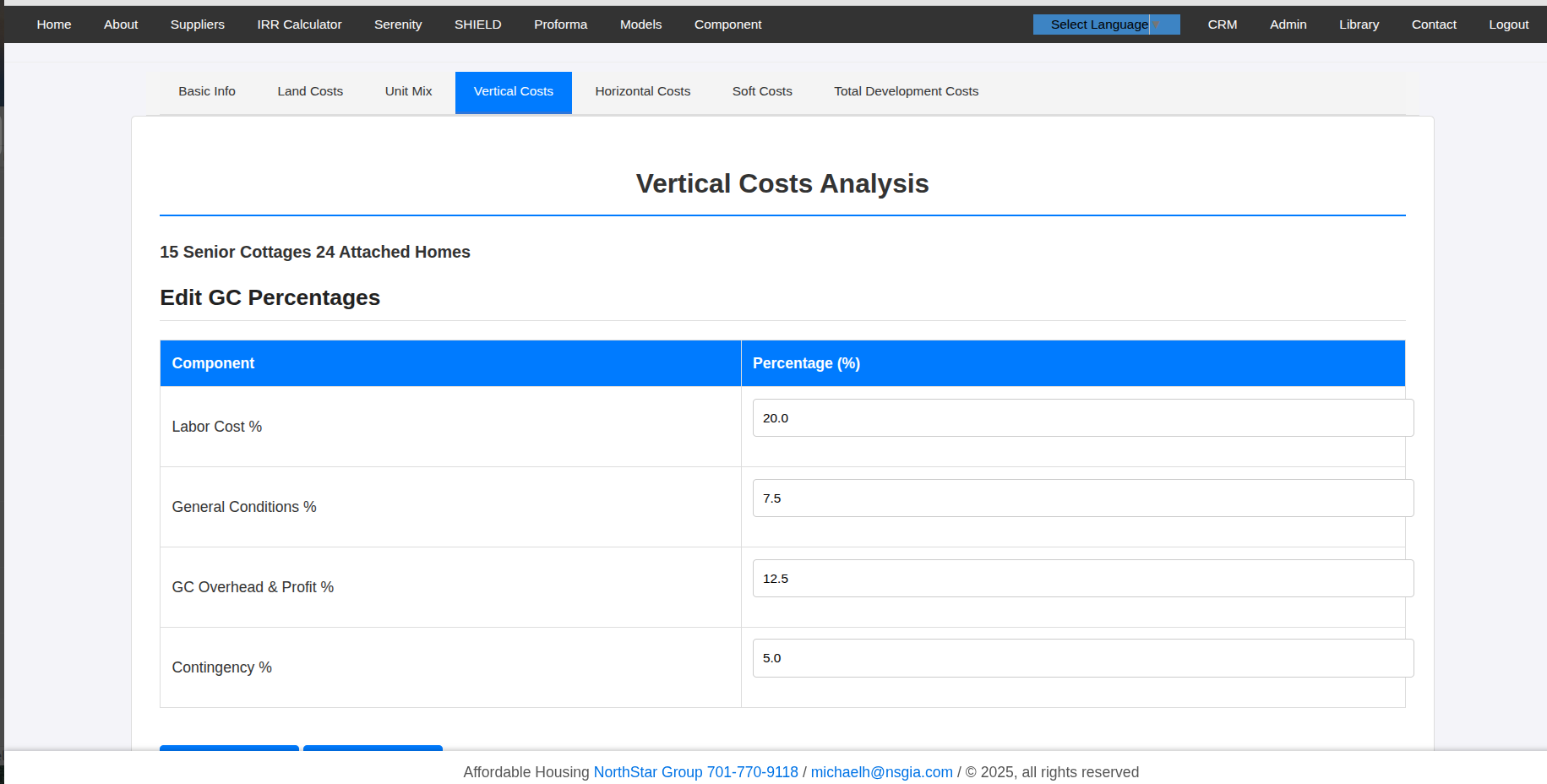

Vertical Cost Analysis - Building-by-Building Breakdown

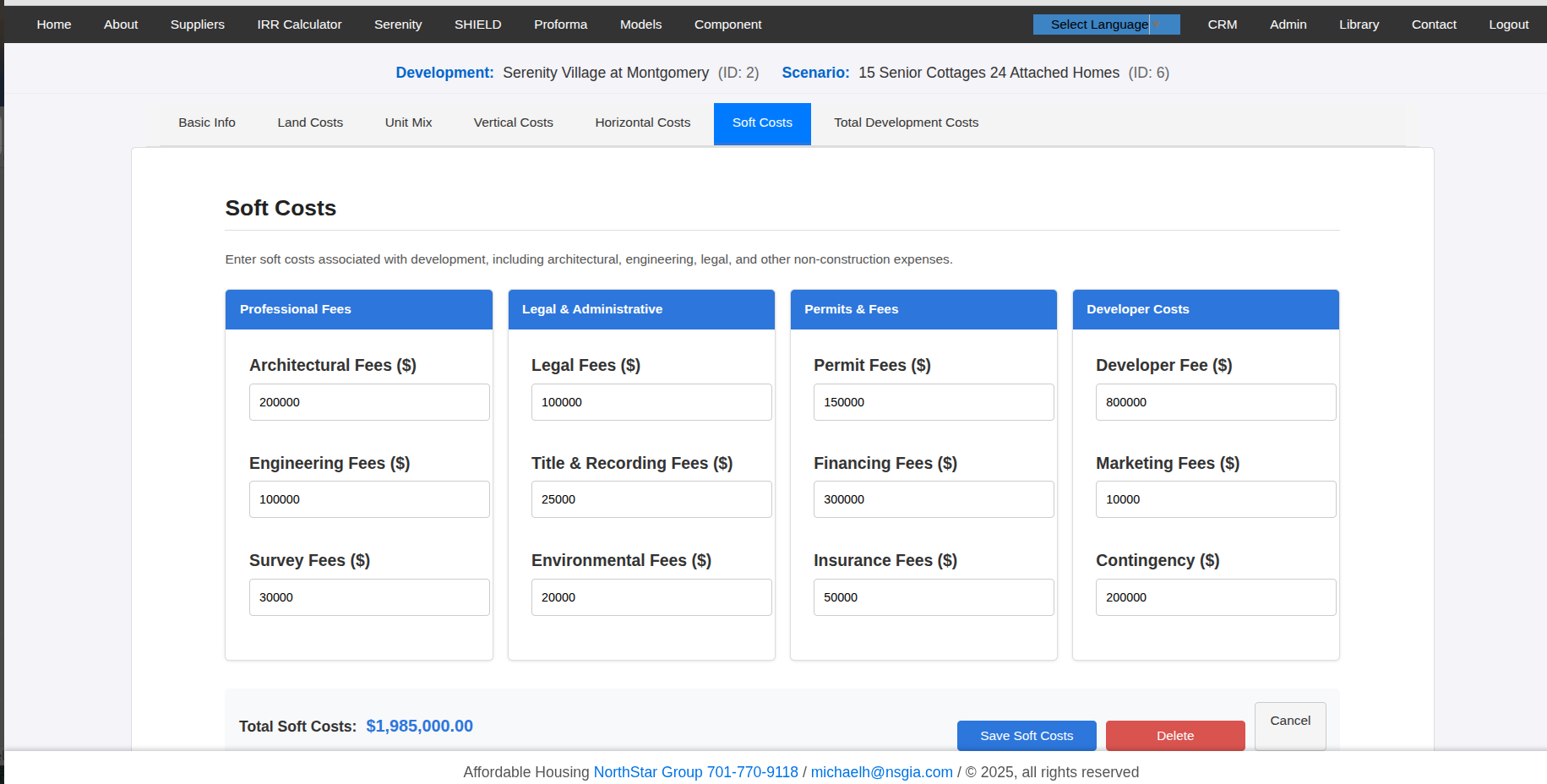

Soft Costs - Professional Fees, Permits, Financing

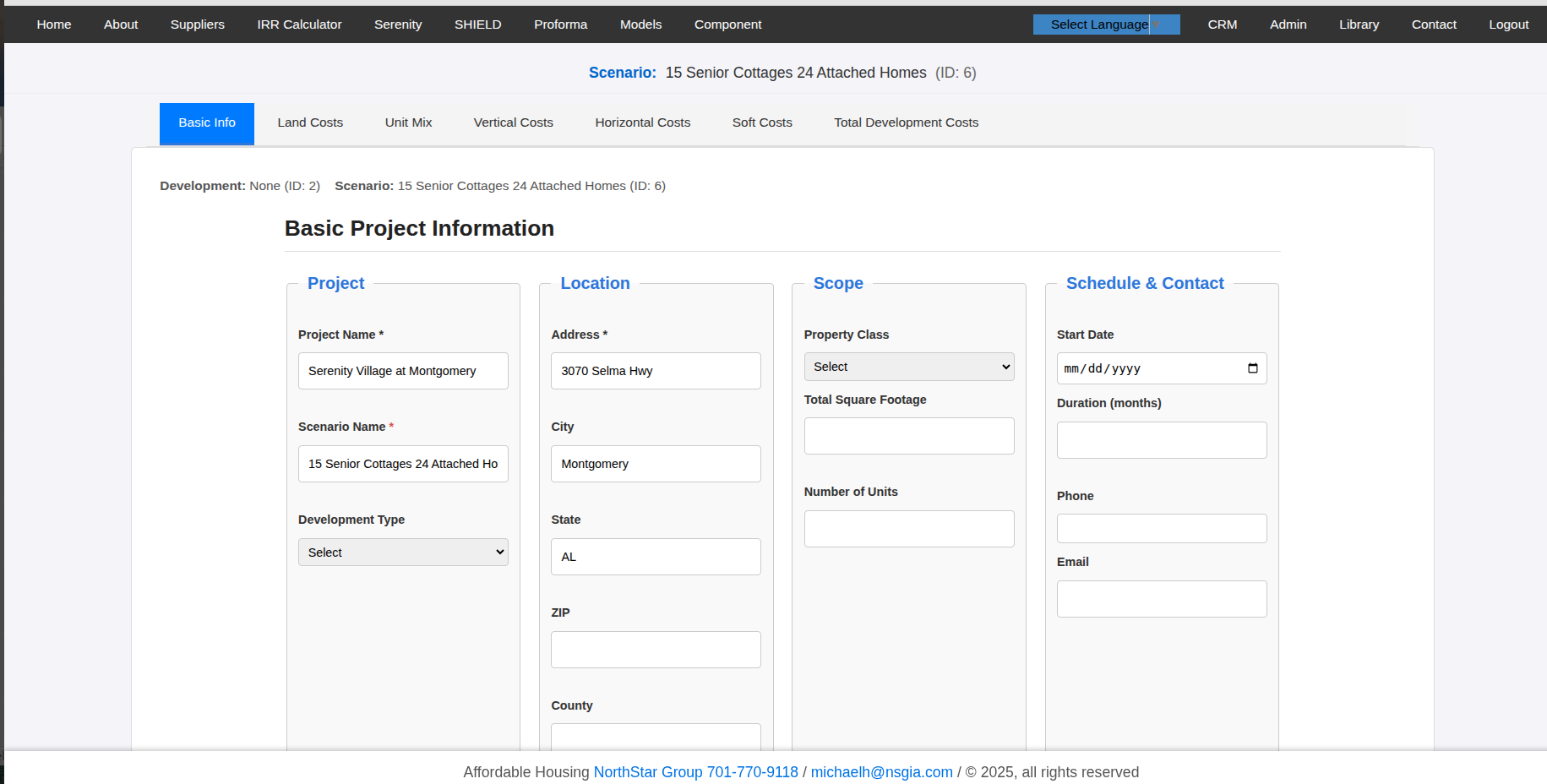

Project Information - Core Parameters and Assumptions

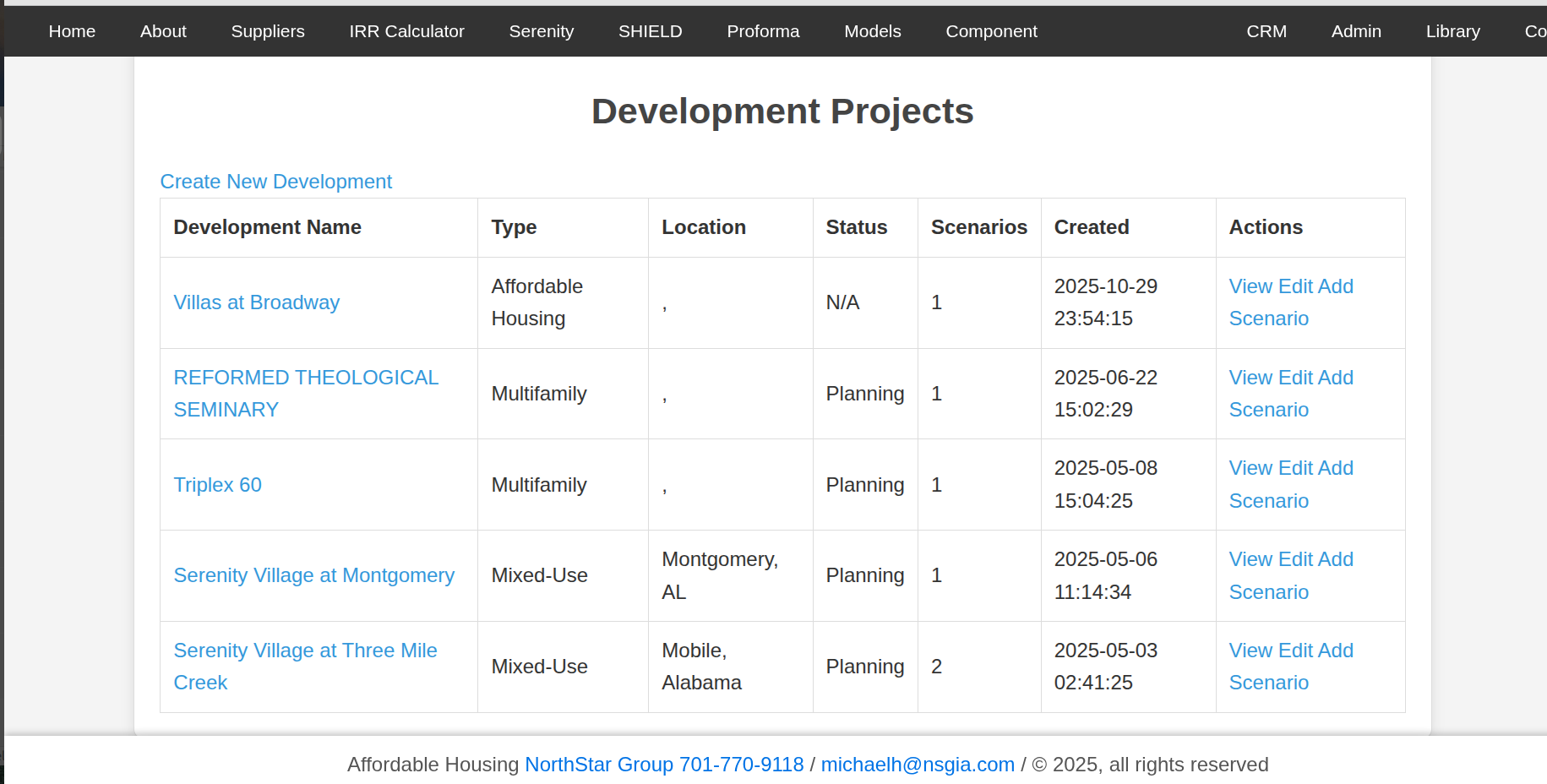

Development Projects - Multi-Project Portfolio View

Development Cost Summary - Complete Financial Analysis

Procurement Process Flow

1. Design Finalization

Architectural and engineering designs finalized with detailed component specifications and performance requirements

2. Component-Level Pricing

Each component individually priced with low/expected/high estimates. Related components bundled for efficiency while maintaining cost transparency

3. Direct Supplier Sourcing

Qualified suppliers submit bids through supplier portal for individual components or logical groups. Multiple sourcing options ensure competitive pricing

4. End-to-End Cost Control

Direct supplier relationships eliminate general contractor markup. Real-time tracking and quality assurance maintain budget integrity throughout construction

System Capabilities

Supplier Qualification Requirements

Professional standards ensure supplier capability and reliability

Technical Qualifications

- Minimum 5 years experience in relevant sector

- Documented project portfolio with similar scope

- Current professional licensing and certifications

- Quality management system certification preferred

- Technical capability demonstration for specialized components

Financial Requirements

- Audited financial statements for past 3 years

- Bonding capacity appropriate to project scope

- Credit references from suppliers and financial institutions

- Payment performance history with trade references

- Insurance coverage meeting project requirements

Performance Standards

- On-time delivery performance >95%

- Quality metrics with <2% defect rates

- Safety record meeting industry standards

- Environmental compliance certifications

- Communication and project management capability

Documentation & Compliance

- Complete project references with contacts

- Regulatory compliance documentation

- Product specifications and technical data sheets

- Warranty terms and service support

- Digital integration capability

Implementation

Platform Integration: The procurement system integrates with component management, cost tracking, and project management workflows. Suppliers access the portal to view specifications, submit bids, track orders, and manage delivery schedules.

Real-time data synchronization ensures pricing updates, delivery schedules, and quality metrics are immediately available to project management teams.

Cost Structure: General contractors mark up materials 15-25% to cover purchasing, storage, non-payment risk, and profit. Direct procurement eliminates this layer. Owner purchases from qualified suppliers, controls specifications, and retains the markup savings.

Component database and supplier network accumulate pricing history and performance data across projects.